- AI Detection of Defects

- Innovative Techniques

Can AI help to make repairs and remake more profitable?

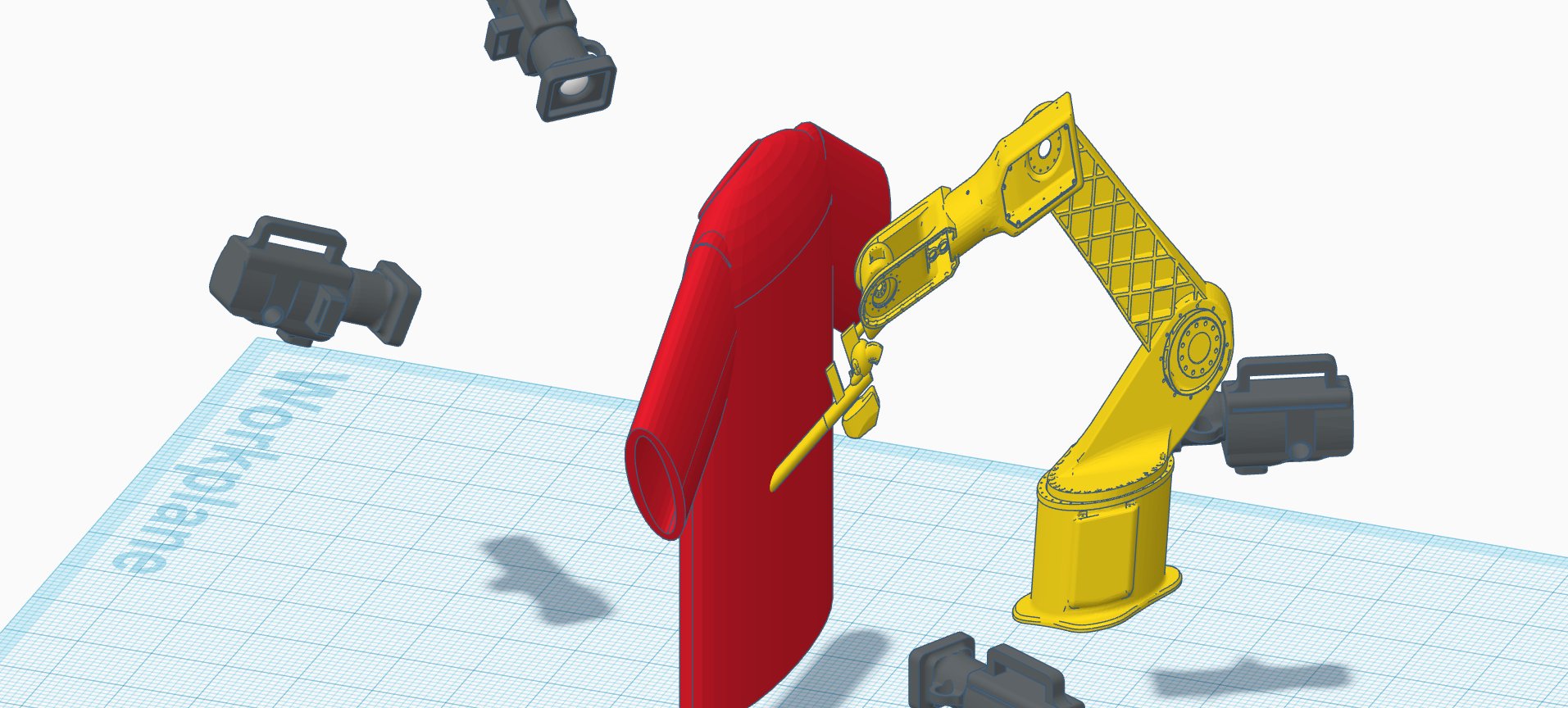

In the projects Microfactory and Circular Movement it is investigated how AI can make the process for repairs and remake more efficient. In a pilot line in DO- tank center the screening of incoming garments is done automatically where the garment passes a station where it is photographed with four fixed and one moving color cameras. The image is interpreted by several custom AI models that look for defects (holes, tears, stains, etc.) and determine the position of the defects, expressed both in 3D as hanging garment and where on a table 2D flat geometry. Based on the type of defect different remake or repair methods can be suggested by the AI model. Remake methods are customized and made in interaction with the customer.

Science Park Borås, Ledai AB

New innovative resource efficient technology

Profitable and sustainable circular business models

Reduction of waste

Today it is often easier and cheaper for a customer to buy new textile products than to repair their favorite items. This is partly due to that repairs of textile products include a lot of manual handling. Skilled workers identify defects and decides and perform the repair method.

As this is labor- intensive it is difficult to scale up repairs as a profitable business model. If some or several of the different steps in the process could be automated it would help to decrease the need of manual handling of products and by that enable profitable business for repairs.

Thinking about technology means thinking about politics and culture, technology on its own will

solve nothing. Technology does however give us a vehicle to envision a system of 0% waste and 100%

circularity with positive impact on society and natural systems. Use of digital tools can minimize

waste in the design process, product development and retail operations. Digital tools enable

manufacturing close to the end consumer that can significantly reduce over production. It can also

help consumers of fashion and textile products to make smarter decisions.

All group objects:

The production of a textile product is a major factor affecting the environmental footprint of the final product. Textile production consists of many stages; there is the production of the fiber, yarn, and fabric, product assembly and post-treatments at all stages. Each one of these stages needs to be considered in order to improve the environmental footprint of the textile product.

One challenge when working with textile production and sustainability is having comprehensive knowledge about the processes and having detailed information available about all stages of production.

Ongoing research and initiatives are finding new techniques and methods for measuring, documenting, and sharing information from the production stages. This makes it possible for brands to more easily document and communicate their products’ environmental footprints, including the production stages.