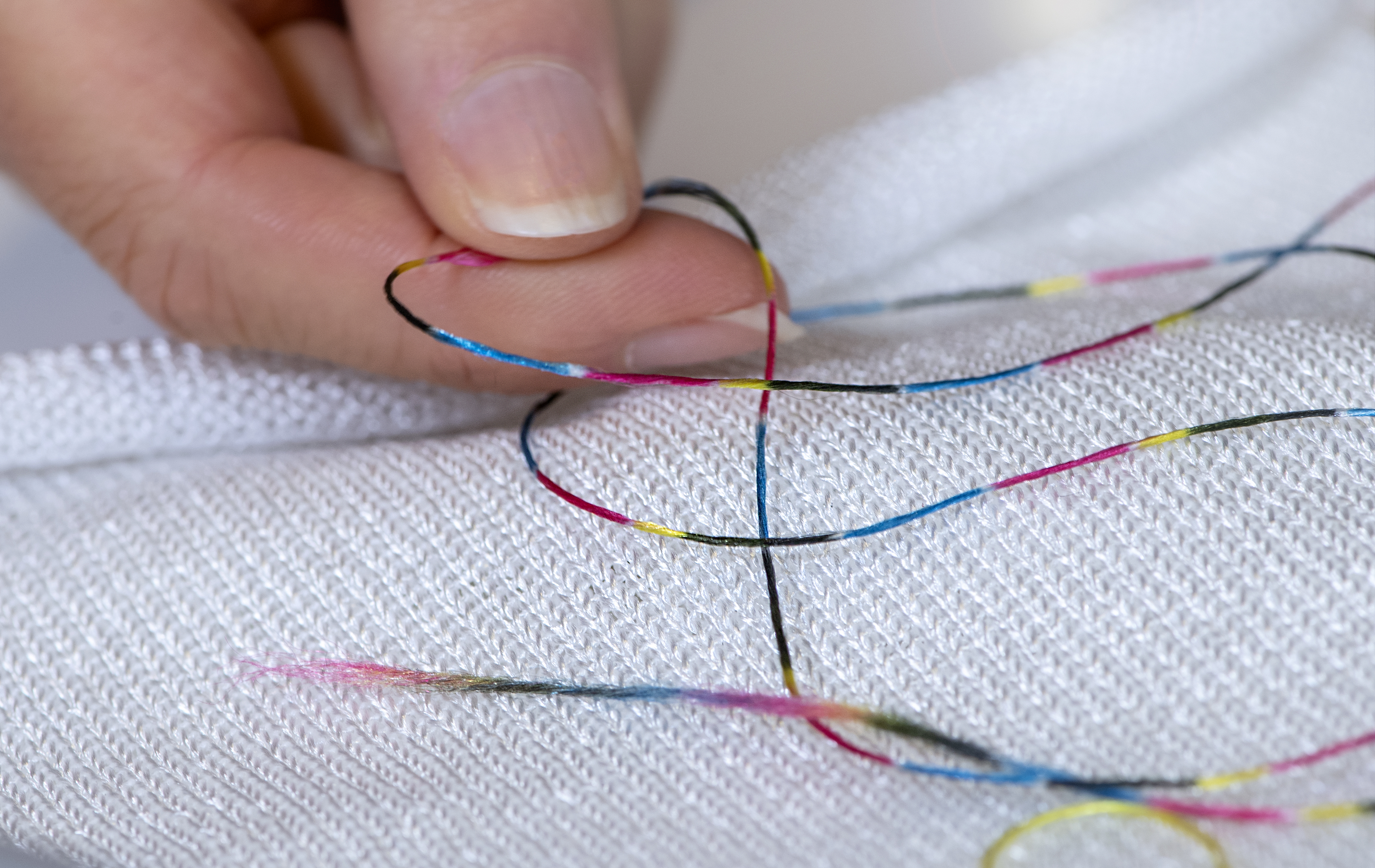

- Yarn-dyed dress

- Innovative Techniques

A knitted half-scale dress made from on-demand digitally colored yarn using the Coloreel technology. This yarn-dye technique eliminates waste and unused stock of colored yarns as well as give a unique creative freedom for the designer. Paired with 3D-knit technology it allows for shorter lead times from order to delivery and increased level of flexibility for the costumer. Coloreel technology is water free and uses a minimum of chemicals.

Polyester

Coloreel, Studio Heijne, Fashion Factory Sweden AB

Over 15 years, different on-demand manufacturing methods has been developed at The Swedish School of Textiles such as digital print and complete garment knitting. Coloreel technology was introduced a few years ago for embroidery and this is the start-up of the development for using Coloreel as on-demand yarn dye paired with knitting in order to reduce set up times in manufacturing and allow for higher flexibility.

Thinking about technology means thinking about politics and culture, technology on its own will

solve nothing. Technology does however give us a vehicle to envision a system of 0% waste and 100%

circularity with positive impact on society and natural systems. Use of digital tools can minimize

waste in the design process, product development and retail operations. Digital tools enable

manufacturing close to the end consumer that can significantly reduce over production. It can also

help consumers of fashion and textile products to make smarter decisions.

All group objects:

Each decision during product development affects sustainability and circularity. To develop products with lower environmental impact, the design team needs to be well aware of each component and process, and their individual and combined effect on the final product and its longevity.

One challenge is having comprehensive knowledge regarding sutainability when it comes to all of the components and processes that are a part of the production and lifetime of the garment. An additional challenge is implementing alternative design methods that do not require virgin components. Ongoing research inspires and shows methods to re-make existing products to have new functionalities and designs with an upgraded look.

With higher traceability when it comes to materials, components, and processes, there are increased possibilities for more conscious decisions. If communicated well, this gives the consumer a better basis for decisions.

The production of a textile product is a major factor affecting the environmental footprint of the final product. Textile production consists of many stages; there is the production of the fiber, yarn, and fabric, product assembly and post-treatments at all stages. Each one of these stages needs to be considered in order to improve the environmental footprint of the textile product.

One challenge when working with textile production and sustainability is having comprehensive knowledge about the processes and having detailed information available about all stages of production.

Ongoing research and initiatives are finding new techniques and methods for measuring, documenting, and sharing information from the production stages. This makes it possible for brands to more easily document and communicate their products’ environmental footprints, including the production stages.