- Gina Lab Transparency Project

- Transparency

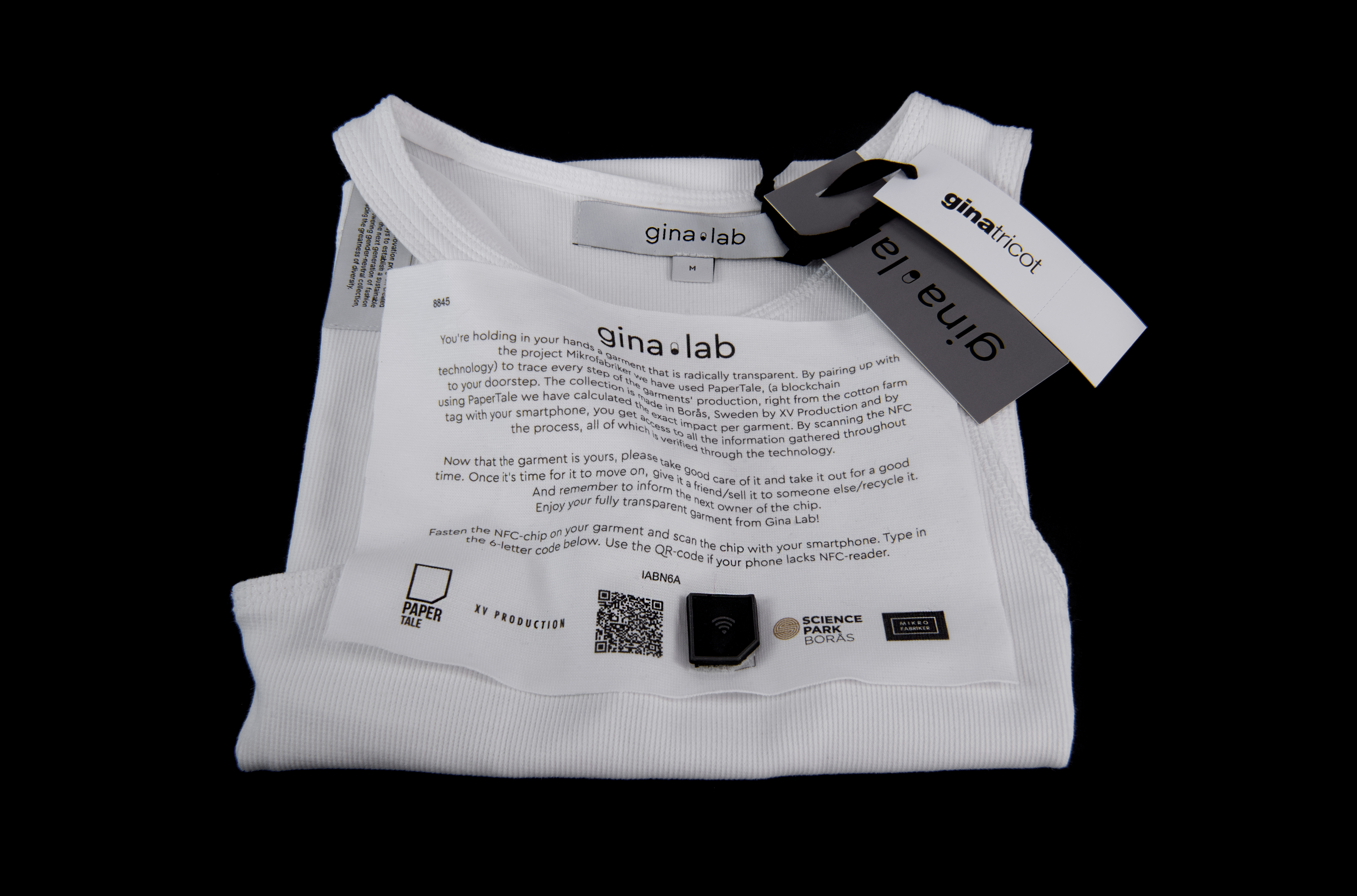

The garments are manufactured in a glocal system as transparent as currently possible. Fibres from Australia, the fabric is made in Pakistan, and the garments assembled in Sweden, close to Gina Tricot’s head office and distribution centre. A NFC-chip is attached to each garment, and through the Papertale-app the customer has full insight to the value chain, both social and environmental. A postponed assembly process allows for less overproduction.

Cotton

Gina Tricot, XV Production, Papertale

The idea behind Gina Lab Transparency project was to explore the possibilities that automated collection of sustainability impact data offers, and push the boundaries of transparency a little bit. Automatization of manufacturing processes offers several opportunities to manufacture textile products closer to market and by doing so, reducing the need to rely on forecasts. That may result in decreased over production and less waste.

How far can we push transparency? Together with Gina Tricot and PaperTale, the project Mikrofabriker wanted to test the boundaries. By using block chain technology, we tried to trace every aspect of the impact the garments in this collection have on people and planet. Ecological, social, and economic transparency.

The block-chain technology by PaperTale allows us to trace every step of the garments’ production, right from the cotton farm to your doorstep. The collection is made in Borås, Sweden by XV Production and using PaperTale we were also able to calculate the exact impact per garment.

By scanning the NFC tag on the sleeve of the garment with your smartphone, you get access to the full journey, impact and craftsmen information gathered throughout the process, all of which is verified through the technology.

All group objects:

Transparency is necessary to ensure that stakeholders in the textile and apparel value chain have access to information in matters that affect them. Transparency is a must for sustainable development.

Accountability is highly valued among customers; in terms of brand building, it comes second to the quality of goods or services. New technologies such as blockchain, RFID, and Bluetooth applications as well as faster data computation enable more possibilities for transparency, traceability, and accountability.

Complete transparency and traceability are still visions. Systems must be created that give all stakeholders in the apparel and textile value chain opportunities to make responsible and informed decisions and to stop corruption.