- Nuno Garments

- The Swedish School of Textiles student projects

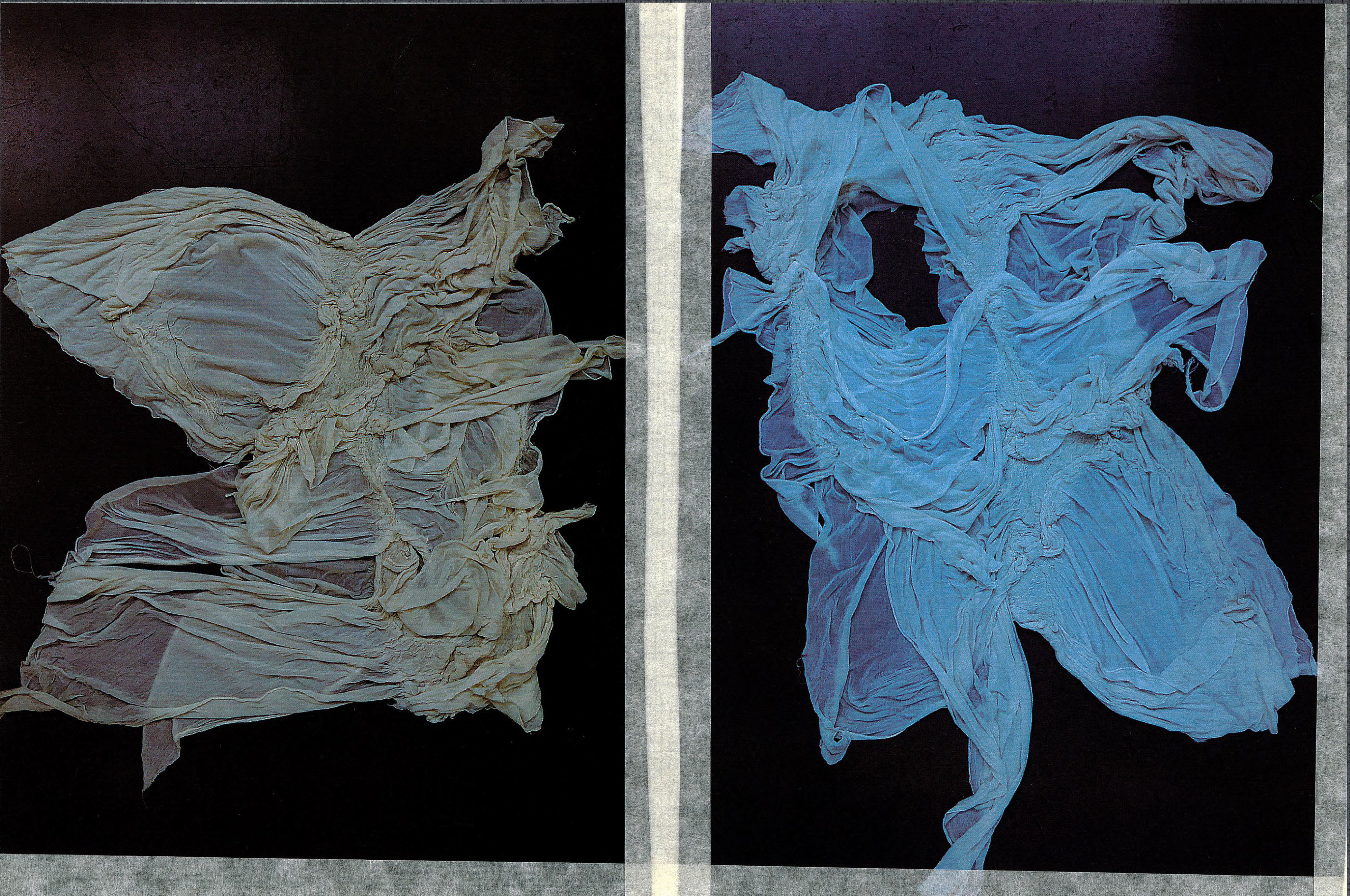

In this BA Fashion graduate collection “Nuno garment”, shrinkage is explored as a concept for creating form. The work seeks to explore how shrinkage can be used to make a flat piece of cloth translate to a garment. Taking place within the field of one-piece-garment-construction ‘Nuno Garments’ questions the conventional way of constructing garments and presents a novel idea for usage of Swedish waste wool in the format of a shrunken five-looks collection.

Wool, viscose, tencel and polyester.

Matilda Sundkler, The Swedish School of Textiles

Each year around 1100-1400 tons of Swedish wool is being buried down or burnt up as a waste product from the meat industry. Wool with bad spin-ability but, never the less a high shrink-ability. The pieces presented in this work have been shrunken into their form by the use of the Nuno Felting technique. ‘Nuno Garments’ seeks to question the conventional way of constructing garments and present a novel idea for usage of Swedish waste wool.

All group objects:

Each decision during product development affects sustainability and circularity. To develop products with lower environmental impact, the design team needs to be well aware of each component and process, and their individual and combined effect on the final product and its longevity.

One challenge is having comprehensive knowledge regarding sutainability when it comes to all of the components and processes that are a part of the production and lifetime of the garment. An additional challenge is implementing alternative design methods that do not require virgin components. Ongoing research inspires and shows methods to re-make existing products to have new functionalities and designs with an upgraded look.

With higher traceability when it comes to materials, components, and processes, there are increased possibilities for more conscious decisions. If communicated well, this gives the consumer a better basis for decisions.