- Repair Patch System

- Re:Make

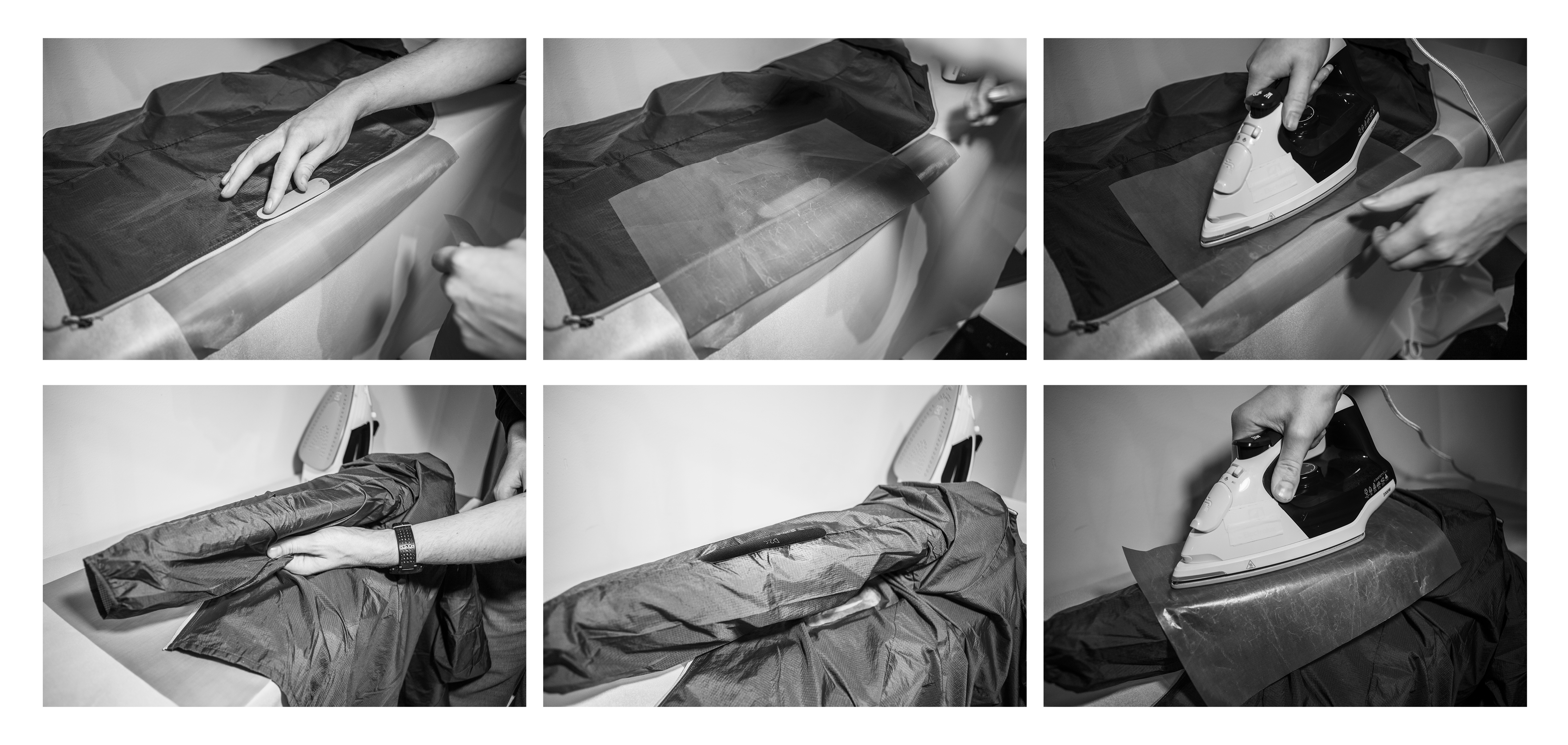

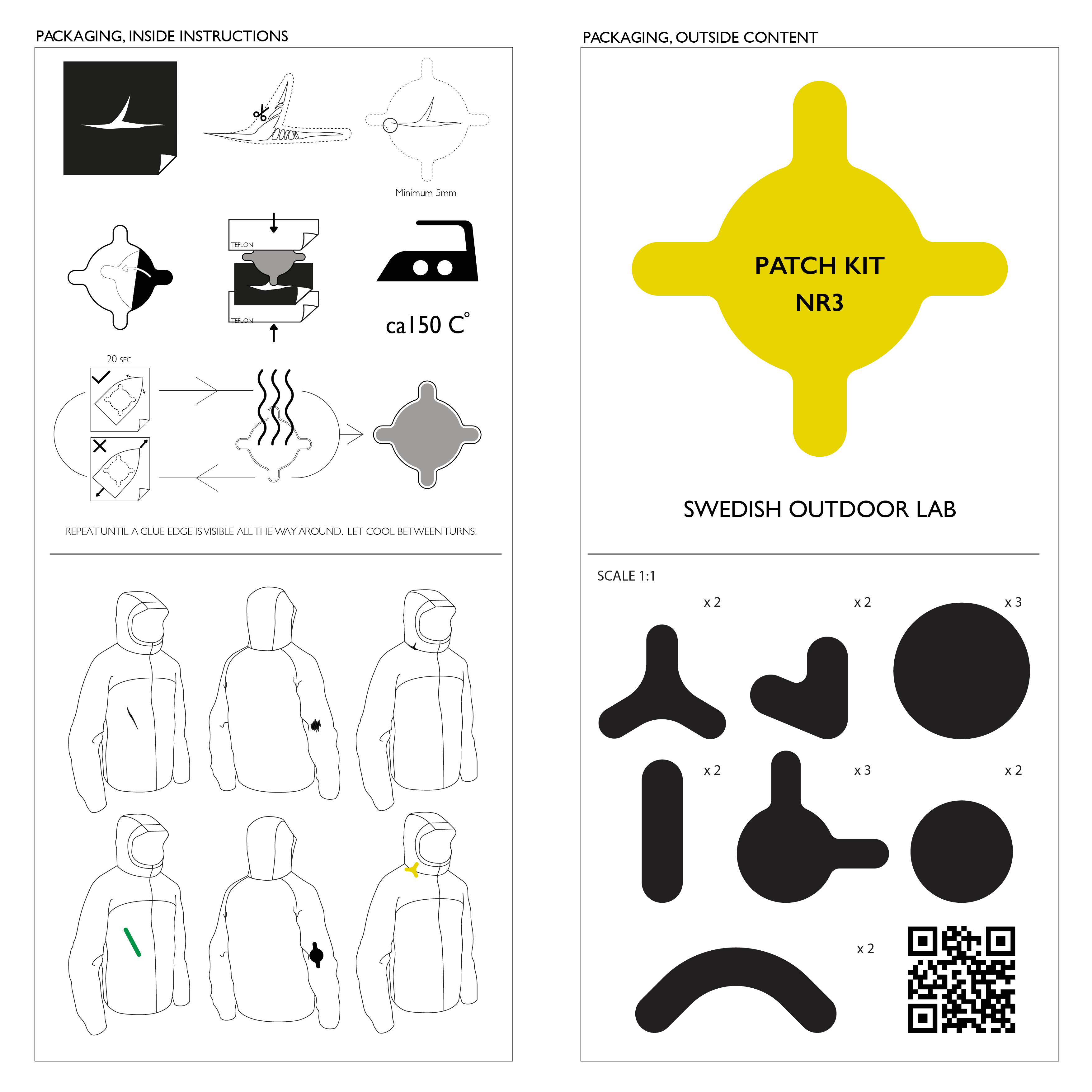

SOL is a service concept for users to easily repair outdoor apparel/gear with their own household iron. A range of textile patches fused with heat activated membranes has been developed. Since they are applied with heat rather than glue a more permanent bond is formed and e.g waterproofing and strength can be retained. The shapes are derived to be applied in different areas of a garment where different levels of flexibility or strength is needed.

Adhesive: TPU membranes

Textiles: Polyester, Polyamide, Polyurethane

Release Liner: Silicone coated paper

S.O.L SWEDISH OUTDOOR LAB

SOL started with the need of mending our own outdoor gear with something else then duct tejp. Today’s solutions and materials used in the manufacturing of outdoor apparel have left them almost impossible to repair for the consumer. After trying existing solutions SOL wanted to find a better one since the possible extended lifespan of a product is for SOL a crucial step in the right direction. So why hide a repair, it tells a story.

Sustainable design methods.

Sustainable consumer behavior.

Efficient use of resources.

Reduction of waste.

The fashion industry is facing problems with overproduction and leftover clothes. One way of addressing these problems is by being creative with clothes seen as “dead garments”, such as garment returns and samples from product development. Turning men’s styles into women’s styles, changing garment shapes, adding prints and details can bring new life to these garments – making them attractive to consumers again.

One way to make remake an attractive business opportunity for established fashion brands is through microfactories. A small-scale textile production line that include all the necessary steps, from sketch and cutting tables to sewing and even product photography.

The result could be a mini collection of remade garments, up to date and in line with the demands of today’s customers. Ready to be sold in the online store in less than a week.

All group objects:

Each decision during product development affects sustainability and circularity. To develop products with lower environmental impact, the design team needs to be well aware of each component and process, and their individual and combined effect on the final product and its longevity.

One challenge is having comprehensive knowledge regarding sutainability when it comes to all of the components and processes that are a part of the production and lifetime of the garment. An additional challenge is implementing alternative design methods that do not require virgin components. Ongoing research inspires and shows methods to re-make existing products to have new functionalities and designs with an upgraded look.

With higher traceability when it comes to materials, components, and processes, there are increased possibilities for more conscious decisions. If communicated well, this gives the consumer a better basis for decisions.

Sustainable consumption may seem contradictive and far-fetched. However, in the space between these words, opportunities for new behaviors, policy instruments, and business models open up, allowing for more conscious consumption.

Platforms such as F/ACT Movement have now been established to help fashion consumers to make more conscious decisions while at the same time enhancing their ability to express themselves through their outfits.

Consumer’s desire to make more sustainable choices, governmental green incentives, and industry’s resource conscious innovation give opportunities to create better systems that allow consumers more opportunities to live out their desire for fashion and textiles.